The biogas industry is undergoing a profound transformation, evolving from a simple waste management technology to a strategic pillar of European energy sovereignty.

However, medium to large-sized plants, given their complexity, require constant monitoring to prevent accidents with very serious consequences.

In the first part of this article, we offer a brief overview of the main trends in this sector.

In the following section, we answer some of the main questions companies ask us about the primary risks to which biogas plants are exposed in the event of fire, pollution, workplace accidents, or interruptions ordered by authorities.

What does a biogas plant consist of?

A biogas plant transforms organic matter (agricultural waste, manure, food waste) into biogas (methane and CO₂) through anaerobic digestion (fermentation without oxygen) in a controlled environment (the digester), producing electricity and heat and a digestate that can be used as fertilizer. In this way, waste is turned into a renewable resource.

In short, how does it work?

Organic biomass is collected and fed into large tanks called “digesters.”

In the absence of oxygen, bacteria and microorganisms decompose the organic material in a process similar to fermentation, producing biogas, which is mainly composed of methane and carbon dioxide, and is collected at the top of the digester.

The biogas is channeled to a cogenerator where an engine, often gas-powered, converts it into electricity and heat.

The solid and liquid residue from the process, rich in nutrients, is used as a natural fertilizer, closing the cycle.

What are the main advantages for companies?

Unlike wind and solar energy, biogas production is independent of climatic factors (solar radiation and wind) and is therefore a very reliable renewable energy source.

The main advantages for companies with biogas plants are evident: the creation of renewable energy (electricity, heat, biomethane) from organic waste, reduced energy costs, greater autonomy, savings on waste disposal, access to incentives, and the creation of additional income.

By installing a biogas plant, it is possible to enhance agricultural and livestock waste and reduce greenhouse gas emissions, turning waste into a resource.

Do companies continue to invest in biogas plants?

Yes, European companies continue to invest in the construction of biogas plants, with a strong push towards biomethane, the refined version of biogas.

Below, we offer a general overview and key reference numbers around this rapidly growing sector.

At the end of 2023, Europe had 1,510 biomethane production plants, with a significant increase of 201 plants compared to 2022. In France alone, another 1,232 projects are under development.

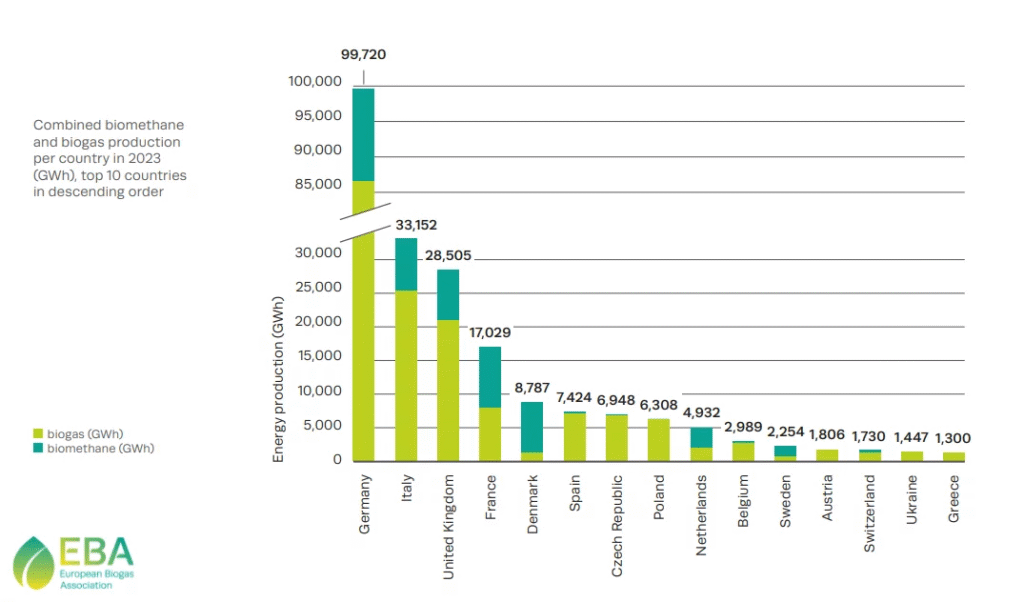

The countries with the strongest growth in biomethane production in 2023 were Italy, France, Denmark, and the United Kingdom.

In 2023, the combined production of biogas and biomethane amounted to 234 TWh, or 22 billion cubic meters, corresponding to 7% of the European Union’s natural gas consumption.

By the end of 2024, private investments committed to the development of biomethane in Europe until 2030 reached 28.4 billion euros.

According to the European Biogas Association, Europe could produce 40 billion m3 of biomethane by 2030.

This potential consists of 74 billion cubic meters from anaerobic digestion (67% of the total) and 37 billion cubic meters from thermal gasification (33% of the total).

Which industrial sectors make the most use of such plants?

Biogas plants are mainly used by industrial sectors that produce large quantities of organic by-products or that require a significant amount of heat and energy for their operations.

Consider, for example, the food and beverage sector, such as beer production and dairy processing, where spent grains, whey, and wastewater are used.

Sugar refineries use pulp waste, pomace, and cassava starch, while companies processing meat convert slaughterhouse waste and offal into biogas.

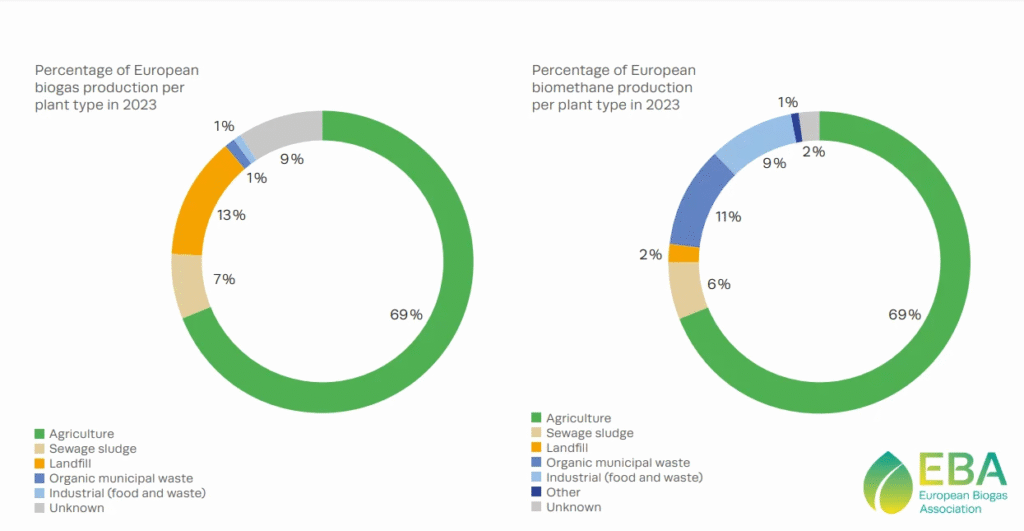

Below, we provide two tables on the percentages of biogas and biomethane use, by sector and by country, from the European sector association’s website (2023 data).

What are the return on investment times?

In 2025, the average payback period for investments in biogas generally ranges from 5 to 8 years, although there are significant differences depending on the size of the plant and the presence of national or regional government incentives.

While small agricultural units can achieve a quick return on investment in 2-4 years, medium and large-sized plants typically require 5 to 8 years to recover the initial capital.

There are cases where industrial-scale plants focused on biomethane production can sometimes achieve investment recovery in 3 years if they use high-yield organic waste.

What should companies do to protect themselves from serious unforeseen events?

Owners and managers of companies with biogas plants must absolutely keep in mind the importance of prevention and maintenance to prevent a major accident (consider a fire or an ammonia and volatile compound leak) from halting not only biogas production but the entire production cycle that depends, in part or in whole, on the biogas plant itself.

In summary, the risks can be as follows:

- methane leaks

- mechanical failures

- fires and explosions

- injuries to employees and third parties from fire, explosion, or microbiological contamination

- biological instability

- odor pollution.

Another risk not to be underestimated is the partial or total shutdown ordered by authorities in the event of an accident or serious irregularities. This is the most feared risk as it interrupts the cash flow from incentives and can lead to the biological collapse of the digester, requiring months to restart production at full capacity.

In the coming weeks, we will dedicate specific insights into the most well-known successful cases, the most innovative risk reduction techniques, and the insurance solutions essential to protect assets and company assets from claims by third parties, neighboring companies, and employees.

Insuring against these risks is important, but it is equally strategic to involve insurance consultants who are well-versed in our sector: they are the ones who conduct the technical visit to our company, and it is thanks to their experience that we can identify unknown or underestimated risks and threats.